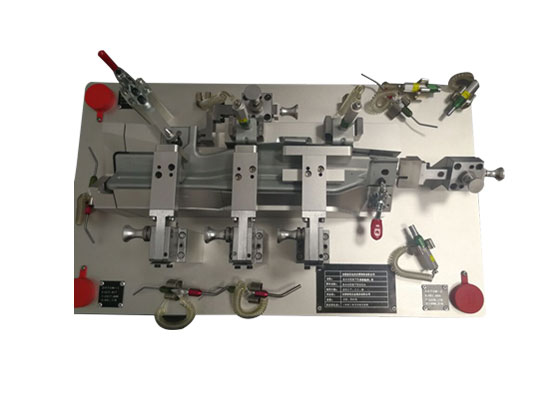

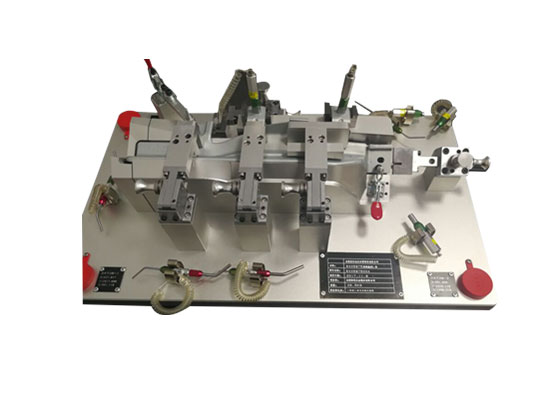

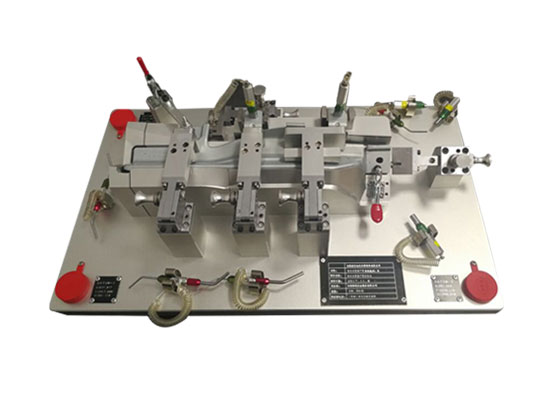

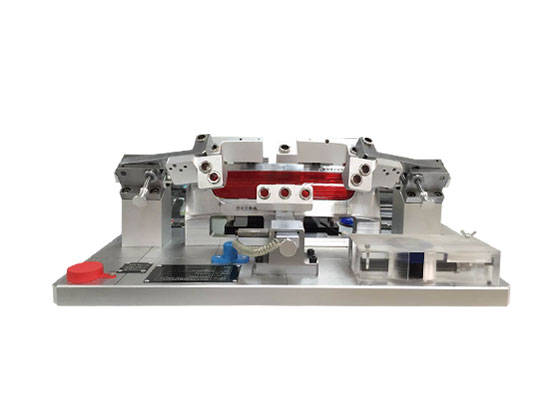

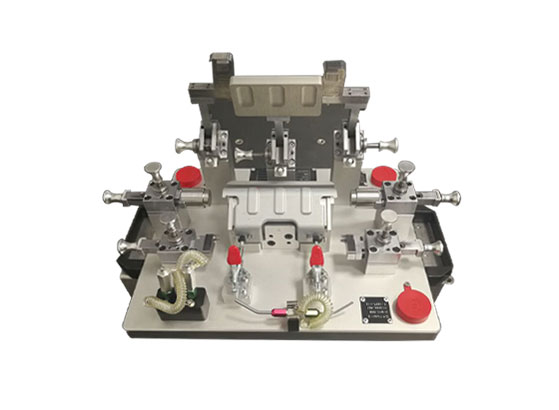

CAR JIGS, JIG AND FIXTURE DESIGN,JIG AND FIXTURE PARTS, TEST JIG FOR AUTOMOBILE AND MOTORCYCLE PARTS

Parts description:

Car Jigs design and make, Jig and fixture design, Jig and fixture parts, Test jig for automobile and motorcycle parts

BASIC INFORMATION

| Parts description: | Car Jigs design and make, Jig and fixture design, Jig and fixture parts, Test jig for automobile and motorcycle parts |

| Metal material used: | Aluminum, Epoxy Tooling board; |

| Process can be used: | CNC machining + Assembly + CMM inspection + Accuracy adjustment + CMM inspection + Be sure Qualified + Packed by polywood Case and Shipped; |

| Tolerance can achieve: | 0.005mm to 0.01mm; |

| Surface Finish: | Anodized; |

| Application Reference: | Auto parts,Car parts, Motocyle parts, Automobile parts; Automotive industry; Lighting system; |

TECH AND BUSINESS SUPPORT

Tech support

- ODM support, tmetal engineers could provide ODM suggestions from cost and manufacturing tech side

- 3D scanning and 3D model building

- 100% CNC custom manufacturing for logo, pattern and other special features

- One stop solution for all mechanical parts from rapid prototype , mold making, to finish parts assembly

Business support

- Sign NDA with all customers if request

- Accept Low volume business

- Could turn back the mold charge for High volume projects; for startup companys or old customers lack

of money, part of tooling charge could be spared to the production piece price

- Competive payment terms for long term copperation customer.

- Logistic support, Tmetal have very competitive logistic chain system, will optimize customer logistic chanel

and offer the best and cost -effective logistic option to all customers

- Customer china local project management and QC managment assitance