HIGH PRESSURE DIE CASTING FROM DONGGUAN SUPPLIER

Parts description:

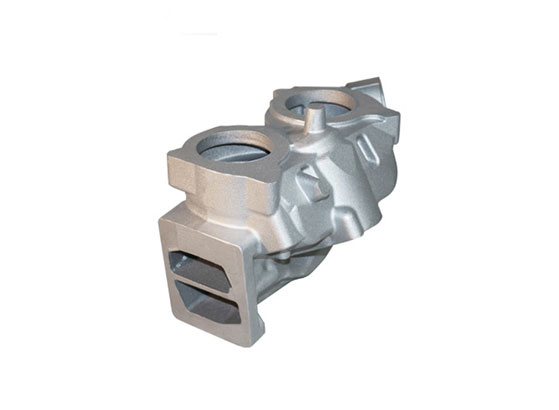

Part Name: Die casting aluminum parts ,cast Al parts,high quality cheap price in Dong Guan of China

Part Material: Alloy , Cooper, zinc , steel,Mg

Tooling Cavity: single cavity and family mould

Process: die casting, deburr, polishing

Surface Treatment: PLATING, ANODIZE, POWDER COATING, BLASTING

Tooling Life: 100K shots

BASIC INFORMATION

| casting Type | high pressure die casting |

| Mold Deign Software | 1.UG 2.Solidwork 3.CAD 4.Mold Flow |

| Casting Weight | 0.05-50KG |

| Product Material | A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2 |

| Processing Tech | Casting, Deburring, Machining, Surface Treatment, Packing |

| Surface Treatment | Sand blasting, polishing, Electroplating, Powder coating, oxidation (black and nature), Painting |

| Casting Blank Size /Dimensions | 2 mm-1500mm / 0.08inch-60inch |

| Industrial Served |

1.Automotive Components 2.Medical and Electronics Parts 3.Communication Technology Parts 4.Other Precision Die Casting |

TECH AND BUSINESS SUPPORT

Tech support

- ODM support, tmetal engineers could provide ODM suggestions from cost and manufacturing tech side

- 3D scanning and 3D model building

- 100% CNC custom manufacturing for logo, pattern and other special features

- One stop solution for all mechanical parts from rapid prototype , mold making, to finish parts assembly

Business support

- Sign NDA with all customers if request

- Accept Low volume business

- Could turn back the mold charge for High volume projects; for startup companys or old customers lack

of money, part of tooling charge could be spared to the production piece price

- Competive payment terms for long term copperation customer.

- Logistic support, Tmetal have very competitive logistic chain system, will optimize customer logistic chanel

and offer the best and cost -effective logistic option to all customers

- Customer china local project management and QC managment assitance